1

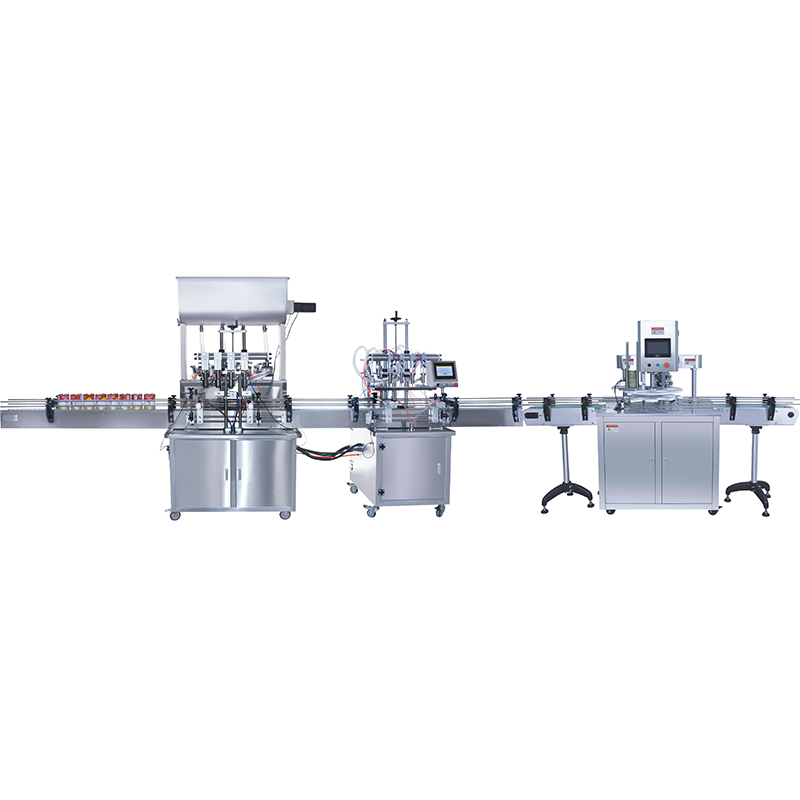

Umshini wokugcwalisa kanye ne-cappingyamukela umgomo we-piston servo drive, ofanele isoso sikachili, ubhontshisi onamathelisiwe, isoso, i-sesame paste, ujamu, isisekelo sebhodwe elishisayo lebhotela, isisekelo sebhodwe elishisayo lamafutha abomvu, njll. nezinhlayiya ezifakwe ku-condiments nokugxila okuphezulu.Ukugcwaliswa kwamasoso aminyene.

Lo mshiniifanele ukuvala nokuvala amabhodlela engilazi ayindilinga futhi amise okukhethekile.Ingumshini we-vacuum capping onamandla amakhulu wokukhiqiza emakethe.Kuyisinqumo sokuqala sokukhiqiza ngezinga elikhulu izimboni zokudla kanye nezimboni zokufaka amathini.

2

Eyenkampaniingilazi ibhodlela ethinini vacuum capping umshiniifakwe i-vacuum system, engakwazi ukuhlanza ebhodleleni lengilazi ukuze inwebe ukugcinwa kwesikhathi eside kwezinto ezisebhodleleni kanye nokunotha kokunambitheka.Lo mshini ungasebenza ngokuqhubekayo.Lapho isebenza, ingakwazi ukuphakela ibhodlela okuzenzakalelayo, ukumunca i-vacuum okuzenzakalelayo, ukufaka i-automatic capping, kanye nokukhishwa kwebhodlela okuzenzakalelayo.Uma ifakwe izinto ezihambisanayo zokulawula umoya womoya, ingakwazi futhi ukwenza umsebenzi wokungafaki ikepisi kanye nebhodlela.

3

3.1Zonke izingxenye zomshini othintana naye zenziwe ngensimbi engagqwali ehlanzekile, enokumelana okuhle nokugqwala kwe-asidi ne-alkali futhi ihlangabezana nezindinganiso ze-GMP.

3.2 Umshini wamukela umzimba we-aluminium alloy, ipuleti lokuvala lensimbi engagqwali, nezicabha ezivikelayo nhlangothi zombili, okuphephile ukuthi zisetshenziswe.Umumo wepulasitiki muhle futhi uyaphana.

3.3 Iphuma ne-conveyor chain plate, isivinini sokudlulisa siyalungiseka, futhi singasetshenziswa umshini owodwa noma ngomugqa wokuhlanganisa.

3.4 Ifakwe isakhiwo esingavuzi futhi singachaphazeli, esivimbela ngempumelelo ukuconsa nokuchaphaza ngesikhathi sokugcwalisa impahla.

3.5 I-hopper inomshini wokunyakazisa, futhi isivinini sokushukumisa siyalungiseka ukuze kuqinisekiswe ukuthi izinto ezigcwalisiwe ngeke zivinjwe.

3.6 I-hopper ifakwe isisetshenziswa esivikela uthuli, okwenza kube nzima ukuthi uthuli namafutha angene ku-hopper, okuqinisekisa ukuthuthwa kwendle kwezinto ezigcwaliswayo.

Isikhathi sokuthumela: Jan-25-2022